TRACKflex

The current quality, productivity, technical development and production process requirements as well as the emerging trends of digitalisation are solved in the Industry 4.0 system. However, these solutions apply to the serial products. It is therefore necessary for customer solutions to act according to the actual production process philosophy.

SYSTHERM s.r.o. completed the three-year development of TRACKflex software for automated design of transfer stations, from the project design after generation of the manufacturing drawings of the mechanical technology, including the design of the electrical installations and electrical switchgear.

The basis of this new TRACKflex software tool was the HESCOpro software that we developed and that is proven by several years of operation, which combines the simplicity of the user approach and many options for the variable solution of the SYMPATIK transfer station. The company itself designed all the components necessary for the safety and functionality of the transfer station. At the same time, it offers the users the option to add other components to the product system according to the standards or specific requirements of the customer.

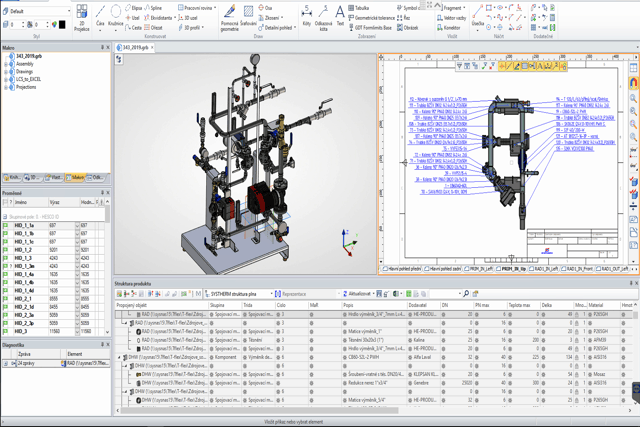

The output of the proven HESCOpro design software is the basis for the next stage of the automation of pre-production preparations. This is the new TRACKflex software, which is parametric 3D CAD software. In practice, the station design from HESCOpro is used to generate the definition files for mutual communication of the two software products.

The layout of the future transfer station depends on the parameters entered for the given model in the 3D software. The software on the basis of the parameters and data in the definition files of the design draws the spatial model of the station in 3D CAD and immediately generates complete drawings. Thus the drawings of the pipes, details of the individual parts of the station or breakdowns of the more complicated systems. Production of stations with such precision preparation and production documentation shall run far more quickly, which affects both the costs and resulting delivery periods.

The deployment of the TRACKflex software in the process of design, manufacturing and sale of the SYMPATIK transfer stations makes it possible for us to submit offers to our business partners in the form of a precision model of the machine technology in 3D, including the project documentation of the electro installations.